Thank you for joining us today at Fresh's Workshop. If this is your first visit, welcome! If you're returning, we appreciate your continued support.

This is the spot where we build and repair all kinds of cool stuff, along with making a ton of saw dust. (Man Glitter.)

During our last session in the Workshop, we worked on a Lazy Susan for the kitchen.

To see that episode, just clicky clicky here:

Before we begin today's project, let's take a moment and talk about shop safety:

Today, we return to the Electronics Shop to work on a digital clock for the nightstand. I wanted a larger one that is easy to see without my glasses.

I have been working on digital clocks for a couple years as I develop a 6-channel audio mixer with a resettable timer. I also wanted to design two clocks side by side for the radio room, one set to EST and the other to GMT.

I had a couple of boards left over from the Ham Radio Clock build, I thought I would put a unit together for the bedroom. The boards had a couple of traces missing, so I had to run a few jumpers to make it work. I also added a couple of 'pull down" resistors as well. I did not want to have to reorder five boards. (My supplier has a five-board minimum order.)

This clock will NOT have an alarm function. I'm retired, so I don't need an alarm.

For all the electronic info, hop on over to my Audio Mixer blog, we have an eight or nine-part blog that is more detailed than what I will have here.

This will be more about the building of the clock and a cabinet rather than the design of the clock.

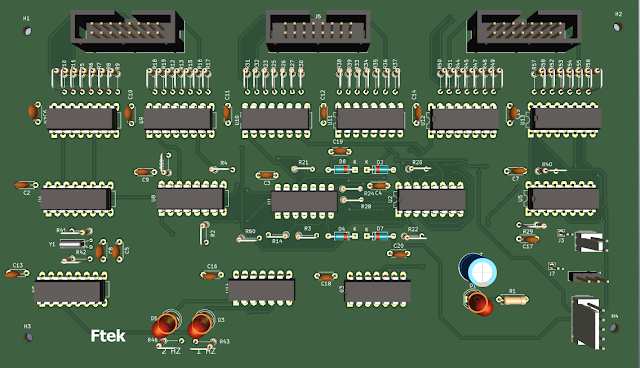

But to perk your interest, here is the schematic. First, the main clock board.

A controller.

And a power supply. +10-15 V in, 5V out.

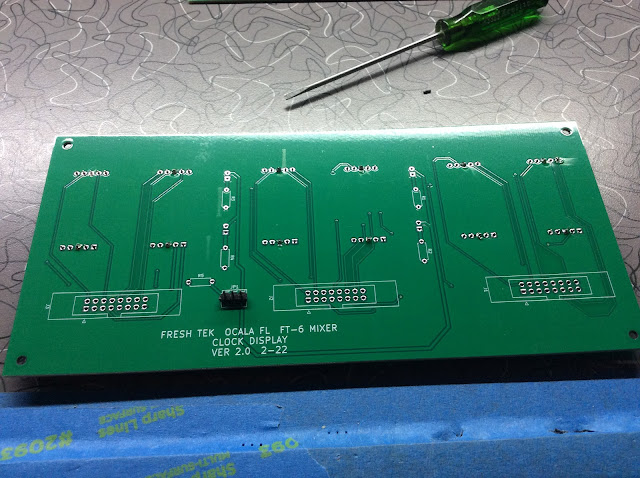

Regarding the circuit boards, there is a main board, as well as a controller and power supply board.

This is designed to feed a 1-second pulse to either LEDs or the decimal point on the displays. I always use the small LEDs to display the seconds. You can choose either function via JP1. The display uses 1-inch 7-segment displays, which are perfect for our needs.

Before we commence construction, I would like to clarify a few points. Although I could have utilized more advanced technology to achieve the same result, I opted for a design that is straightforward to understand and repair in case of malfunctions. Additionally, the process was enjoyable and kept me occupied during the evenings.

Let us proceed. We have boards and the components. We will begin with the displays. You will observe that I frequently use "sockets" in my electronic work. This allows for easy replacement of parts if necessary.

I utilize 40-pin sockets for the displays and the LED seconds displays. Simply cut off the desired number of pins.

I place the pins on the display and insert it into the board. I tape it down, turn it over, and solder the pins place. I repeat this process for each segment. This keeps everything in proper alignment.

Repeat with the jumper and the IDC cable sockets.

And the resistors.

And the display board is complete.

Yes, I did realize that one of the displays was upside down!

Now that the display is complete, we will proceed to the clock. We will use our bench power supply to run the clock until we create the power supply and cabinet.

I always start with the power sections. I install the filter capacitor, LED resistors, and LED. Then I power it up and ensure it is functioning properly. Next, I move on to the counter section, which generates the 1 Hz pulse to make the clock count. The heart of that section is the 4060-chip counter and a crystal. Be careful when soldering the crystal. Ensure you use a clamp as a heat sink to avoid burning out the crystal. I learned this the hard way.

Install all the 4060 and the 4013 components as well. Now you can check with power. Yep, it counts.The far-right LED indicates the Power (5V). The two LEDs on the left are the counter LEDs: one for 2 HZ per second and the other for 1 HZ per second. The 1 HZ count goes to the main clock counters.

Next, we move on to the main clock, starting with the seconds count, which will range from 0 to 9. Then the tens of seconds.

Now that you understand the process, I will proceed to assemble the rest of the parts (checking each section as we go) and then demonstrate the outcome.

Here it is on the bench, functioning perfectly. The next steps involve the controller and a power supply.

I experimented with about dozen ideas for the controller (as detailed in my other blog). We need to send +5V pulses to the minutes and hour displays, as well as a 5V pulse to reset the seconds.

It is challenging to obtain a good pulse with just a switch due to the nature of switches, which results in "switch bouncing" or multiple pulses. This makes it difficult to set the clock accurately.

After numerous unsuccessful attempts, we discovered a chip specifically designed to eliminate "switch bounce." However, it switches a ground pulse instead of a 5V pulse. I resolved this issue with a CD4049 Hex inverter that converts the ground pulse to the required 5V pulse.

Now, let's put the Controller together. Wait, we can't do that until we order the controller boards.

And here is the power supply. I found a wall wart that gives me 10.5 V. out. I started with a +15V supply, but thought it created too much heat on the heatsink. The wall wart worked much better, and the power supply runs cooler.

So here we have the 'guts' to our project. (We will add the controller as soon as the new controller boards arrive)

We still need to go out to the shop and create a cabinet for this. I am considering a plexiglass cabinet in order to show off the insides. I did this with an Audio Mixer many years ago. It did not work as I desired, but it looked great.

We will also finish up the 3-switch controller as well.

But before we finish up this project, we have a TV to hang on the wall. That's next here in Fresh's Workshop.

See you then!

Be sure to visit some of my other blogs:

AROUND THE KITCHEN - SEE WHAT I COOK

BRIARWOOD - YOU CAN READ MY NOVELS

AUDIO CONSOLE - WHERE I AM BUILDING AN AUDIO MIXER

DISCLAIMER The information contained here is for ENTERTAINMENT purposes only. Working with woodworking tools can be dangerous. The user of these tools should have a basic knowledge of woodworking and be familiar with the proper use and safety precautions associated with these tools. Always wear appropriate personal protective equipment, such as safety glasses, ear protection, and a dust mask. Always use the tool in accordance with the manufacturer's instructions and guidelines. Always maintain a safe and organized work area.

.

No comments:

Post a Comment